Making a Statement with Potain Self-Erecting Crane

December 1, 2021

Pennsylvania Contractor Unlocks Productivity with Potain Igo T 130 on Unconventional Build

February 5, 2022Labor Shortages Showcase Benefit of Potain Tower Cranes on Jobsites

Tower cranes reach and reliable performance execute the jobs of multiple workers, not to mention the tasks of more conventional equipment. Kelly Hadland, CEO of Compass Equipment, based in Gilbert, Arizona, explains why Potain self-erecting cranes are a reliable and cost-effective solution to the labor shortage issue in home construction.

Construction labor shortage has been an issue in the U.S. for over a decade — and the problem is only growing worse as a result of the ever-increasing demand for housing, and the acceleration in total housing starts, which jumped from approximately 1 million single-family and multi-family units in April 2020 to a rate of roughly 1.5 million by the end of that year.

An Associated Builders and Contractors analysis of U.S. Bureau of Labor Statistics data therefore predicts that construction companies will need to hire 430,000 more workers than they employed in 2020 — and a higher growth rate scenario could boost that number to nearly a million. Still, a survey from the Associated General Contractors of America suggests 72% of respondents anticipate labor shortages to be the biggest hurdle in the coming year, with some unable to accept new projects because the labor simply isn’t available to handle them.

There are, however, ways to reduce the scale of the problem. Looking Up asked Kelly Hadland, CEO of Compass Equipment — which works closely with homebuilders and other contractors in fast-growing Arizona — how Potain tower cranes can offer a dependable and cost-saving solution.

Looking Up: How’s business in Arizona?

Kelly Hadland: Just like many other locations around the country — California, Nevada and Colorado, for example – there’s a lot of work around. In Arizona alone, there’s claimed to be over US$40 billion in construction work on the books, when in a typical year it would be around US$5-6 billion!

LU: So what’s the issue at hand specifically?

KH: As the amount of projects has increased substantially, so has the need for workers — the question is, where do all those workers come from? The fact is we had a labor shortage even before the pandemic coupled with the surge in housing demand has only exacerbated the issue, so the pool to pick from has been reduced.

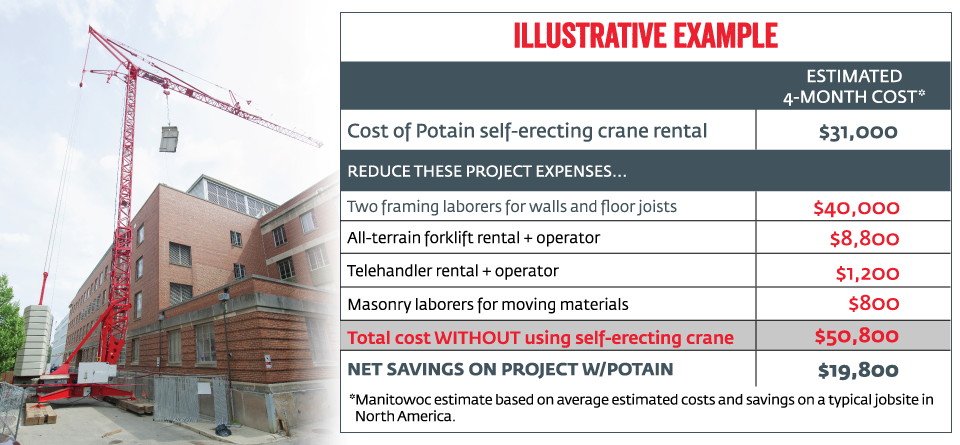

Construction of low-rise buildings continues to grow and self-erecting tower cranes excel at these types of jobsites, helping reduce machinery rental costs. Since self-erecting cranes are always at the site ready to work, they help get jobs completed faster, resulting in significant labor savings.

These cranes are ideal for light steel and wood material projects, prefabricated walls, trusses and roofing materials. They can do it all.

LU: What’s being done to resolve the problem?

KH: Some projects are providing financial incentives for workers to show up to work every day. Construction projects are having to find creative, outside-the-box ways to attract talent, whether that is in project management, sales, engineering, surveying, or the rest of it. Contractors are having to rethink ways of attracting workers.

But at Compass, we have been promoting ways to cope with the labor shortfall by using self-erecting and city cranes for a wider range of tasks. Cranes do the work faster and more efficiently than manual labor. Plus, contractors can save money by prefabricating more materials offsite, decreasing the need for manual labor on the jobsite. We also believe contractors can attract talent by using the best equipment available in the market today.

LU: Many people will think of cranes as being purely for lifting huge loads rather than a replacement for manpower — what sort of tasks are we talking about here?

KH: We’ve talked about the value of using self-erecting cranes and small city tower cranes on large jobsites for years, but now we’re seeing them gaining ground on the smaller sites too. They are frequently used for a lot of light material projects, whether steel or wood. This type of project has traditionally required a lot of people and a lot of forklifts that will place trusses, plywood, lumber, etc., in random locations, and then a crew of workers will haul those piece by piece to where they are needed.

Or, you can have one crane serving a large area from one location, moving those same materials, or picking up a prefabricated wall and setting it in place without multiple guys having to hold it steady. Ultimately, these cranes can do a lot more of that sort of work, a lot faster with better reach, and a lot safer with far fewer employees.

LU: Is it possible to quantify the potential labor savings?

KH: One of the definitions of work from an engineering standpoint is: force times distance, in this instance, force meaning weight. How much weight are you moving, and how far do you have to move it? Then time goes into the equation: how fast can you move it? You can accomplish that using many people, or you can do all that work with one tower crane.

I would go so far as to say that one crane can move bundles of materials faster and safer than 10 workers can. If we had 3,000 lbs of plywood sitting on the ground and had to move it up a few floors, give me the right operator and the right crane and we’ll do it faster than 10 strong guys. So, using the right technology, and the right tools to do things safely and cost-efficiently, I think we’re really going to see a spike in the demand for these products. They may not be able to solve the materials shortage but can be a big benefit in helping overcome the labor shortage.

Even in normal times, we are adamant that self-erecting tower cranes are a cheaper and safer way of building — now, with the labor shortage, it’s going to become even more of a necessity.

LU: You’re saying that using a crane shouldn’t be a last resort, and it’s cheaper too?

KH: Let me say this to all general contractors and subcontractors, particularly the framers, light-steel folks, roofers, and wall manufacturers: these cranes can add a lot of value.

In the past, people have been so stuck in the “I’m going to use 30 guys, four forklifts, and it’s going to take us four months,” mindset. With a self-erecting or city crane, you’d manage fine with 20 people instead — think about how much money that would save, assuming those 30 original workers were even available.

If you divide the bare rent price of an Igo T 85 A self-erector by how many hours it can work in a month, it’s going to be the cost of two or three workers, maybe one worker in certain areas. That’s one crane doing the work of 10 people for just 10-30% of their wage — that is a powerful message in today’s labor shortage crisis.